Jor-Mac provides On-Time, High-Quality, Cost Competitive metal fabrications to Original Equipment Manufacturers (OEM’s). We produce from simple to complex parts utilizing a broad range of material including hot rolled & cold rolled steel, stainless steel, aluminum, galvanized and galvannealed product. We operate in multiple facilities with over 100,000 square feet of state- of -the -art manufacturing technology. Our experienced engineering team using 3D modeling software will quickly take you from development to production.

Jor-Mac can partner with you to fulfill your metal fabricating and assembly requirements. By reducing your product cost, improving quality and availability, Jor-Mac can help reduce your capital expenditure requirements and focus on product development, sales and marketing. Jor-Mac has it all: engineering, reverse engineering, prototyping, fiber laser cutting, welding, powder coating, assembly, kit

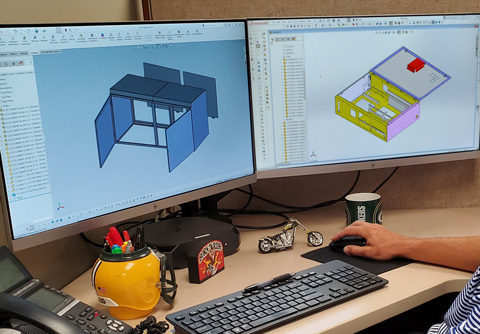

Engineering & IT / ERP Resources

Our expert engineers can partner with you to help prototype new products or improve your current ones. The engineers at Jor-Mac are experts at Design For Manufacturing (DFM), where we help you reduce production and material costs by providing solutions for eliminating unnecessary parts and processes while increasing quality and value.

Jor-Mac’s engineering expertise:

- SolidWorks™, AutoCad™, SigmaNest™

- Engineering, 3D Modeling & Programming

- Fully Integrated Manufacturing ERP System with Capacity Planning and EDI

- UL 508A & NEMA Enclosures

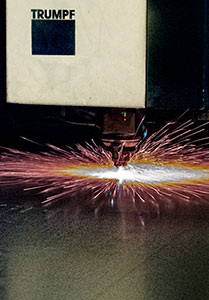

Fabrication & Machining Equipment

- 5 Fiber Lasers with Automation

- (1) Trumpf 12,000 Watt Fiber Laser with Automation

- (1) Trumpf 8,000 Watt Fiber Laser with Automation

- (3) Trumpf 4,000 Watt Fiber Lasers with Automation

- (4) CNC Turret Presses – Amada AE 2510 NT, Amada PDGA 354, VIPROS 255, VIPROS III

- (16) CNC Press Brakes – Amada, Cincinnati, Ermaksan, Toyokoki & Trump (40-240 Ton)

- (1) CNC Shear – ¼” to 10’ Capacity, CNC Gauging with Stacker

- MIG & TIG Welding

-

(8) Spot Welders – up to 100 KVA

- PEM Automatic and Manual Insertion Presses

- CNC Machining Centers – Hass VMC

- CNC Band Saw, Rolls, Iron Worker & Metal Finishing

- Outsource Partnerships: Machining, Stamping, Tube Bending & Plating